East Of Yuhua Road, Shijiazhuang City, Hebei, P. R. China 053600.

+86-311-85293775

+86-311-85293779

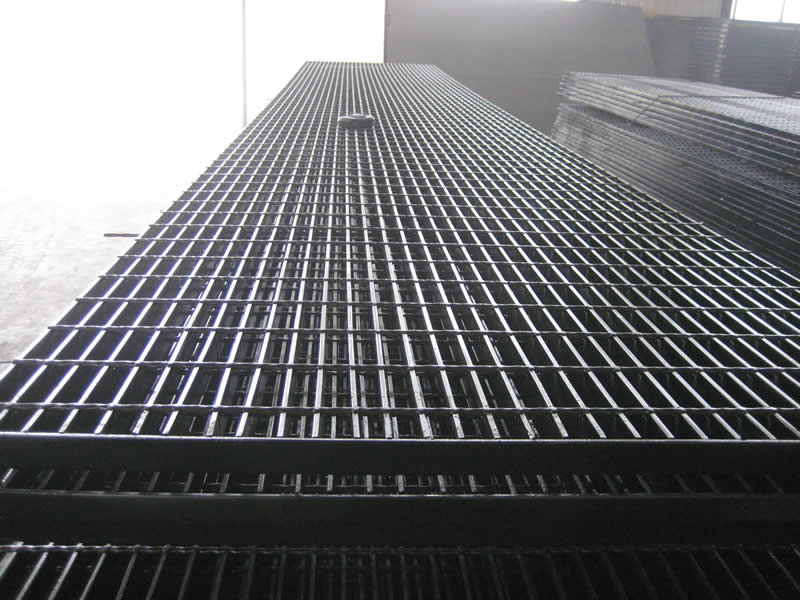

Metal Gratings

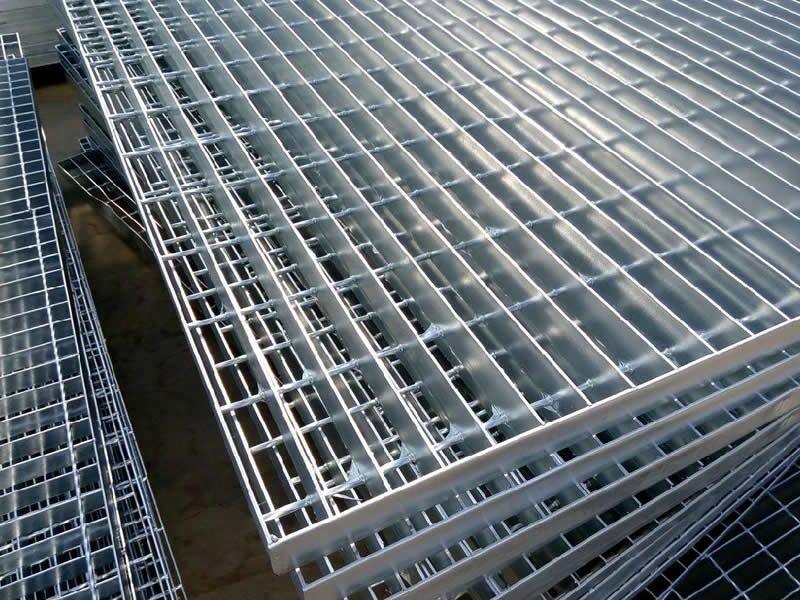

Steel grating by the grid load on certain flat steel bar and spacing Affairs with the high pressure resistance welding machine welded together on the original plate. With the character of high-intensity, light structure and good ventilation. It be widely used in corridors, bridge, ditch cover, covers, ladders, and so on.

Raw Material:

Grid load flat steel bar: High-quality low carbon steel, galvanized steel, stainless steel, alloy steel.

Horizontal pole: Q235A or 304 stainless round steel, twisted square steel, square steel and hexagonal steel.

Classification: Welded steel grating, standard pressure lock grating, dense grating, ditch cover and ladders

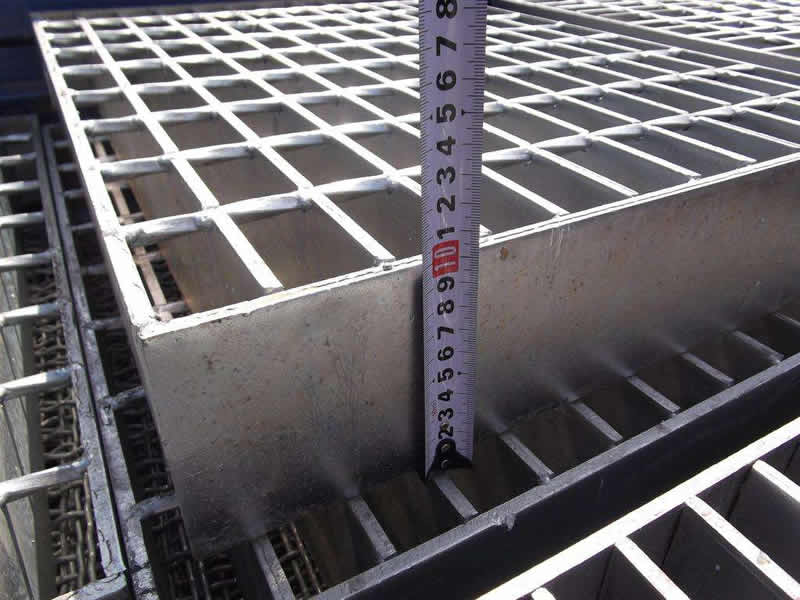

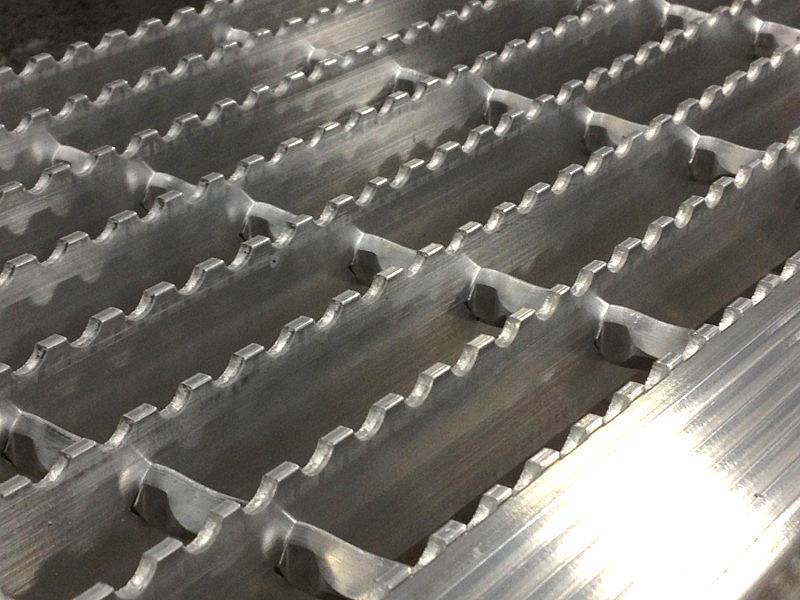

Features: Strong steel structure made it have a high carrying capacity; With good corrosion resistance through surface by hot-dip galvanized; light structure easy to lifting; flat serrated have the character of safety and anti-slip; ventilation, lighting, heat, explosion-proof.

Finish treatment: Hot dipped galvanized, cold dipped galvanized, spray painting, dip anti-rust oil, can prevent oxidation.

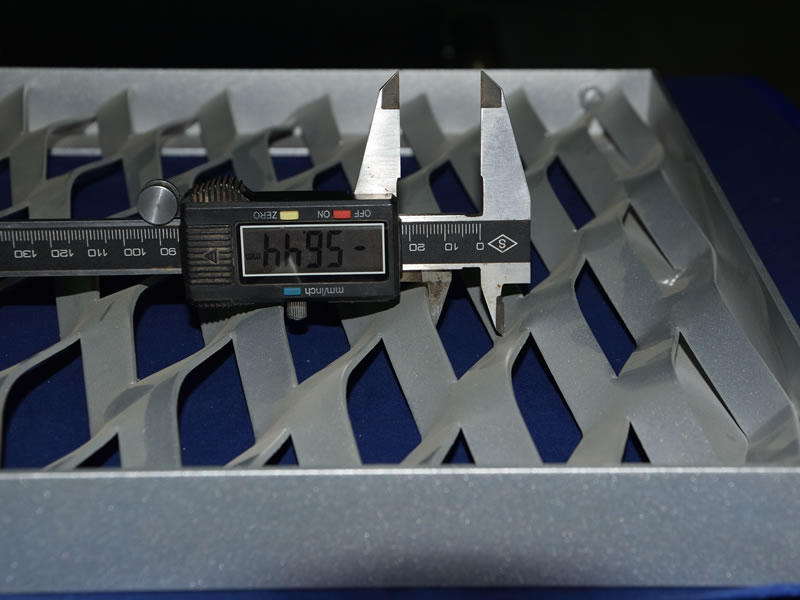

Surface type: Flat type, serrated type, I shape type(According to requirement made different protective treatment).

Application of steel grating:

- All kind of plant, such as power plants, chemical plants, steel plants, oil plants, paper-making plants, and so on. Used as platforms.

- All kind of shipping, used as platform of ramp, channels, pumping stations and engine room.

- All kinds bridge, such as side road of railway bridge, suspension bridge, trestle bridge. Used as panel shop.

- Used as drain covers and road fence at municipal engineering and road.

- Other uses, such as oil platform, wharf road, washing platform, tower platform and building fence, and so on.

| Specification list of Steel Grating | |||||||||

| Series No | Vertical Bar Spacing | Horizontal Bar Spacing | Specification of Supporting Flat Steel Width X Thickness (mm) (mm) | ||||||

| 20×3 | 25×3 | 32×3 | 40×3 | 20×5 | 25×5 | ||||

| 1 | 30 | 100 | G203/30/100 | G253/30/100 | G323/30/100 | G403/30/100 | G205/30/100 | G255/30/100 | |

| 50 | G203/30/50 | G253/30/50 | G323/30/50 | G403/30/50 | G205/30/50 | G255/30/50 | |||

| 2 | 40 | 100 | G203/40/100 | G253/40/100 | G323/40/100 | G403/40/100 | G205/40/100 | G255/40/100 | |

| 50 | G203/40/50 | G253/40/50 | G323/40/50 | G403/40/50 | G205/40/50 | G255/40/50 | |||

| 3 | 60 | 50 | - | G253/60/50 | G323/60/50 | G403/60/50 | G205/60/50 | G255/60/50 | |

| 32×5 | 40×5 | 45×5 | 50×5 | 55×5 | 60×5 | ||||

| 4 | 30 | 100 | G325/30/100 | G405/30/100 | G455/30/100 | G500/30/100 | G555/30/100 | G605/30/100 | |

| 50 | G325/30/50 | G405/30/50 | G455/30/50 | G500/30/50 | G555/30/50 | G605/30/50 | |||

| 5 | 40 | 100 | G325/40/100 | G405/40/100 | G455/40/100 | G500/40/100 | G555/40/100 | G605/40/100 | |

| 50 | G325/40/50 | G405/40/50 | G455/40/50 | G500/40/50 | G555/40/50 | G605/40/50 | |||

| 6 | 60 | 50 | G325/60/50 | G405/60/50 | G455/60/50 | G500/60/50 | G555/60/50 | G605/60/50 | |